How does screen printing work?

The principle is very easy..

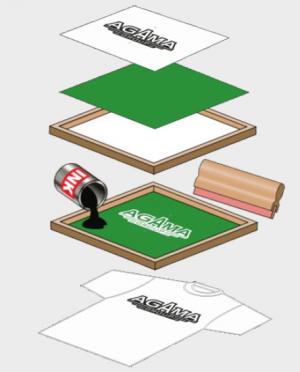

Screen printing ink is applied to the substrate by placing the screen over the material. Ink with a paint-like consistency is placed onto the top of the screen. Ink is then forced through the fine mesh openings using a squeegee that is drawn across the screen, applying pressure thereby forcing the ink through the open areas of the screen. Ink will pass through only in areas where no stencil is applied, thus forming an image on the printing substrate. Once the screen printing job has been completed, the ink and emulsion are washed off the screens. The screens are then ready for new emulsion to prepare them for the next print job. The more colours the design has, the more screens the job will require.

Screen printing is ideal for repeating contracts and can be used for production of small and large series of products. Excellent coverage of rich shades of final print with significant relief with 3D effect can be achieved by using a thick layer of paint.

Transfer printing ( thermal transfer ) is the proces in which the design is first printed on to a flexible non-textile substrate and later transferred to printing textile by a separate process. It is used mostly for textile where screen printing is not suitable because of its shape or material it is made of (caps, bags, sportswear ..) The sublimation transfer works on similar principle.